Cold Room Sandwich Panel Manufacturer in China

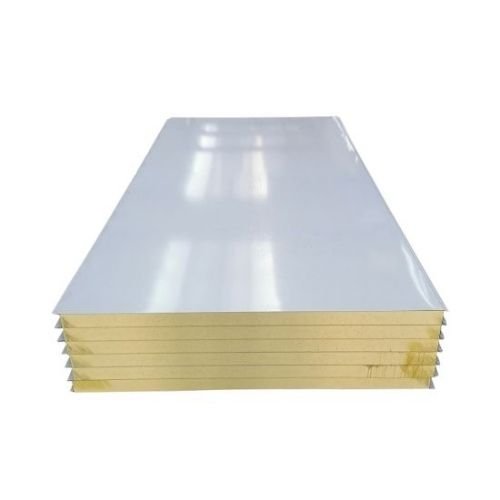

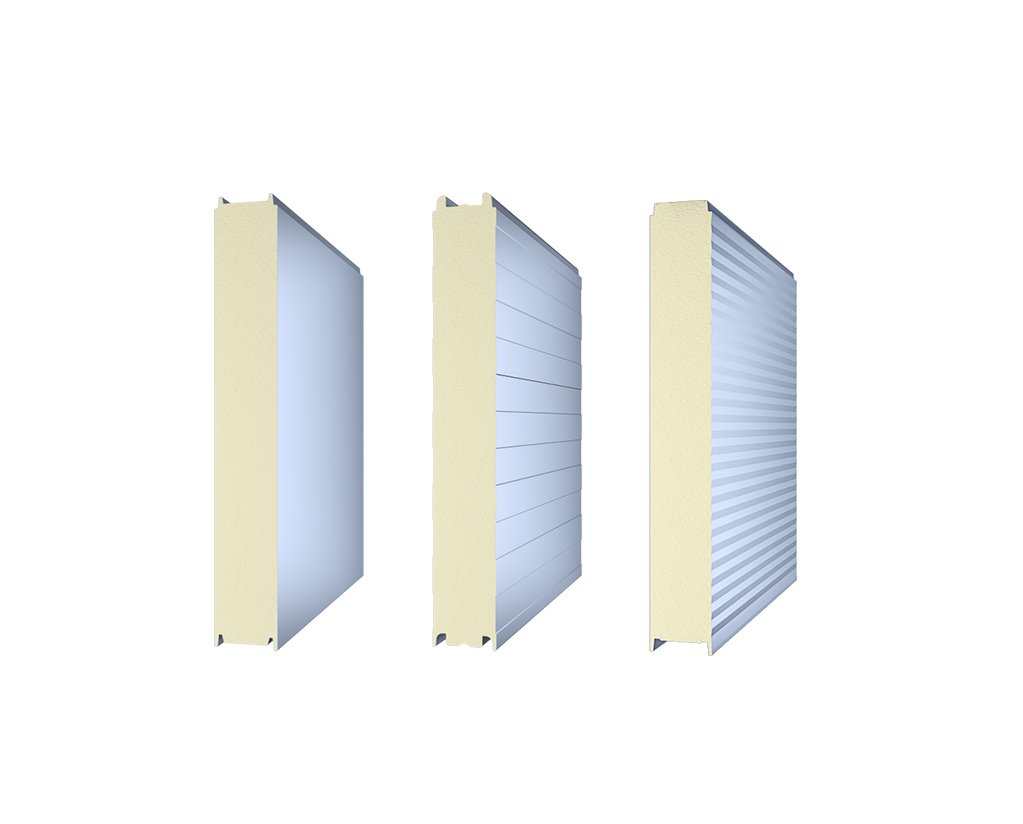

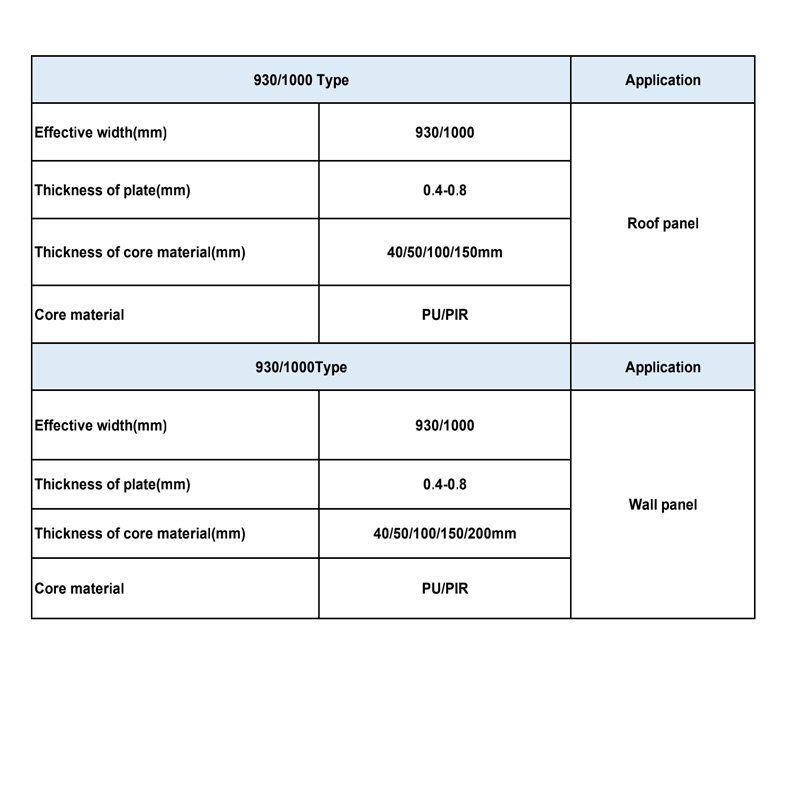

Luton is a professional manufacturer of cold room sandwich panels, available in standard thicknesses ranging from 30mm to 300mm. It can also be customized according to your specifications. Our sandwich panel for a cold room can be available in insulation core, including PUR and PIR.

- Custom panel thickness

- Extremely lightweight

- Durable and corrosion-resistant

- Fewer installation times

Luton Cold Room Sandwich Panel

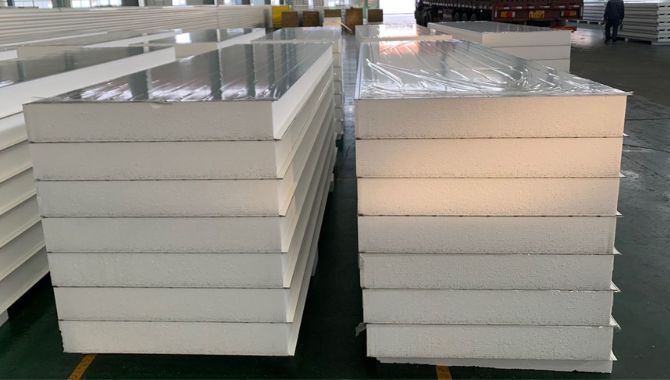

Luton cold room sandwich panel is composed of two galvanized steel sheets, profiled, and pre-lacquered. It encloses insulating cores which consist of durable polyurethane high-density foam. Our cold room sandwich panel is manufactured to provide excellent thermal insulation, which can guarantee great performance in refrigeration panels. It is also easy to install with outstanding results, great strength, and acquires sanitary profiles.

Adopt the new generation PU PIR Pentane-blown B1 foam as the rigid core material, which boasts excellent heat insulation and fireproof performances. Ultra-high temperature stability and fire rating, zero Freon emissions, energy saving, and eco-friendly, thus able to be widely used in industrial building and cold storage projects.

Luton manufactures cold room sandwich panels exceeding various international standards. We use excellent-grade steel materials from domestic first-line steel mills like Baosteel, Bluescope, Masteel, and more. Custom design, label, packaging, and other specifications are acceptable.

Contact us now!

Cold Room Sandwich Panel

Luton Panel Company provides this kind of high-quality and strong cold room panel with a different sales-service offer such as online technical support, onsite training, onsite installation, free spare parts, etc.

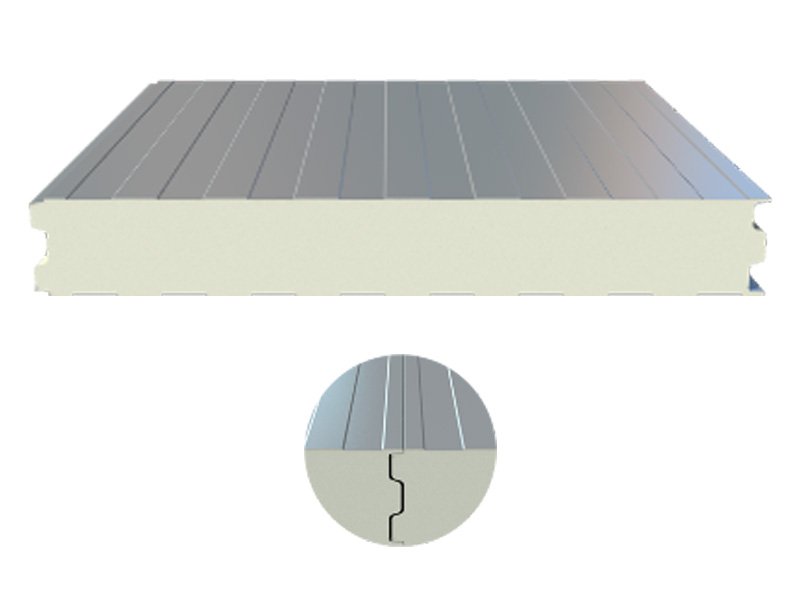

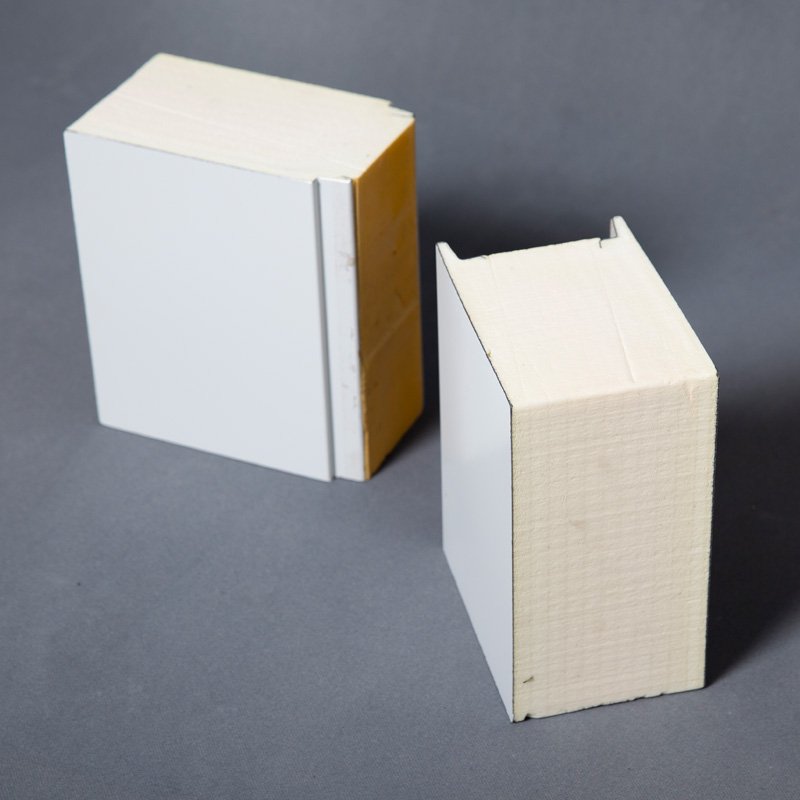

The polyurethane cold room sandwich panel has a Camlock design fastener and strongly silica gel that ensure the tightness of the installation of the cold room. This panel can prevent unwanted air leakage.

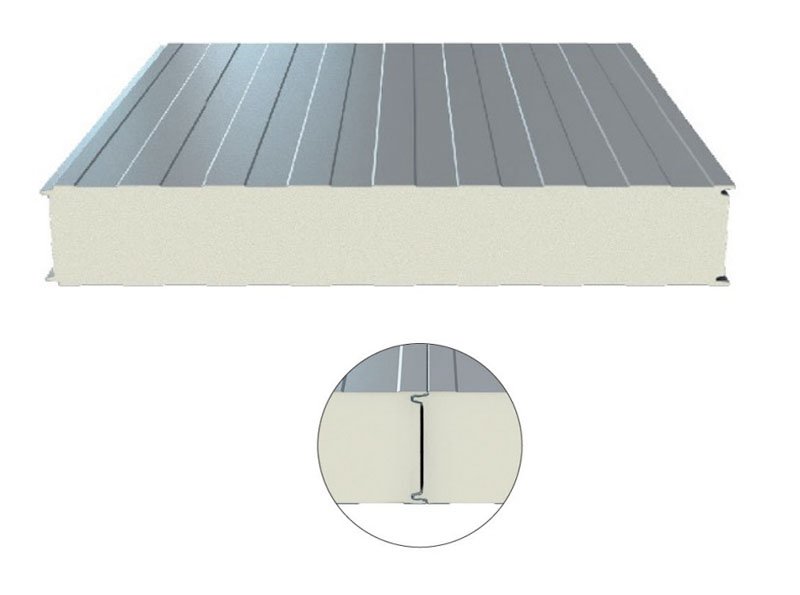

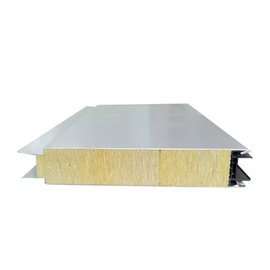

The Luton Panel rock wool sandwich panel for roofing has a light dead weight, excellent shearing resistance, high mechanical strength, high durability, strong corrosion-resistance, etc.

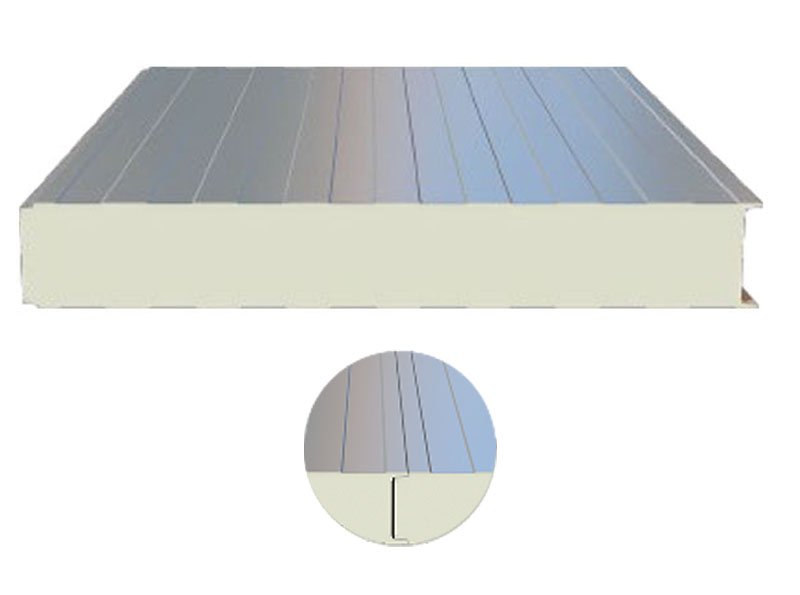

PU cold room sandwich panel has a heat-retaining material that uses PIR/PUR foam with hear-preservation, temperature preservation, weight sustaining, heat insulation, water-proof, etc.

These heat-insulated cold room wall panels can be customized at a maximum length of 11.8m according to the dimension of the container. Very to install, excellent anti-corrosion effect, and has a durable zinc-coated cam lock.

The Luton Panels offer this high-density sandwich panel for cold room storage with excellent lightweight features, rapid construction speed, and heat insulation. Perfect for the various industry that uses cold storage room.

Unique Materials for Cold Room Sandwich Panel

Luton uses environmentally friendly and thermal insulation materials to produce sandwich panels for cold rooms. These materials include the following:

- PVC Foam Plastic: The advantages of PVC foam plastic material are low water absorption, low thermal conductivity, high durability, and high compression.

- EPS (Polystyrene Foam): Resin is the primary base material of polystyrene. They are lightweight, alkali and acid resistant, and low-temperature resistant. In a cold room, most of the polystyrene foam is quick to absorb water.

- XPS (Extruded Polystyrene Foam: It has good thermal insulation, low thermal conductivity, excellent moisture resistance, and heat insulation.

Cold Storage Panel

Cold Storage panel advantages

1. Low thermal conductivity of≤0.020. It has a high-efficient thermal insulation effect.

2. A high percentage of close area ≥90% and low moisture absorption ≤3%. It has an excellent waterproof effect.

3. It adopts the unique concave-convex type which improves the tightness of the socket of the panel. High viscosity, high strength≥220 and good load resistance performance≥2450.

4. Excellent flame-resistance level B.

5. Wide scope of temperature resistance.

6. The panel is even and stable.

7. The dimensional stability is good≤2.

8. It is a green and environmental-friendly product.

9. Easy and convenient construction.

10. Fast and quick installation.

Insulation Effect – Compared with different core materials

-

The core material adopts a new generation of the rigid PU PIR foam composite material system, which effectively blocks heat conduction, thereby excellent thermal insulation performance

-

Rational joint design, great thermal insulation effect, and superior mechanical performance

-

Excellent thermal insulation performance, high economic benefits, reduced air loss, and solar radiant heating, thereby lowering energy consumption & costs, CO2 emissions, and building energy consumption

-

Meet various major fire protection standards in the world

-

Lower volatile organic compound (VOC) emissions, environmentally friendly and sustainable

PUR

In terms of raw material proportioning and process output, PUR products employ the globally advanced six-component online automatic (SIMENS) mixing and pouring technology and have realized six-component continuous foaming for the first time in China. With the technology, the mixing and proportioning process may be finished in an online way; the formula may be adjusted according to environmental changes; air feeding and mixing devices may be used to make raw material mixing more even and foam finer, thus producing high-strength, energy-saving, and environmentally friendly building boards.

PIR

Polyisocyanurate is called PIR for short. For the composite boards developed , excessive isocyanurate is added and ring structure and higher isocyanurate index are employed in the compounds to form compact PIR products, thus ensuring greater stability and excellent heat and fire resistance for the internal rigid foams. Experiments show that the products can endure a temperature up to 200ºC in short time period or to 160ºC for long time.